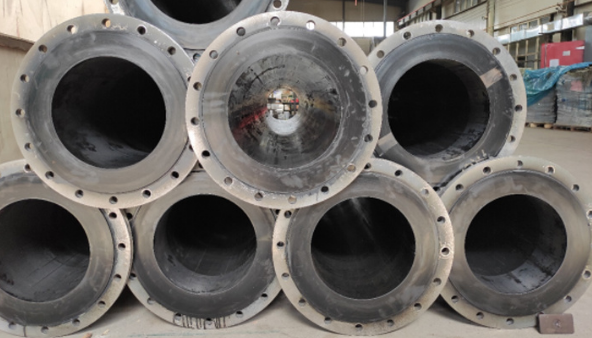

Rubber lined steel pipes

Release time:

2025-04-01

The production of rubber - lined steel pipes involves a series of meticulous steps. First, the steel pipes are fabricated with precision. The steel used is carefully selected and processed to ensure the right thickness and strength. For high - pressure applications, thicker steel walls may be required, while for less demanding situations, a more cost - effective thinner steel can be used.

Rubber - Lined Steel Pipes: A Versatile Solution

Rubber - lined steel pipes have emerged as a highly effective and versatile piping option in various industrial sectors.

1. Manufacturing Processes and Quality Control

The production of rubber - lined steel pipes involves a series of meticulous steps. First, the steel pipes are fabricated with precision. The steel used is carefully selected and processed to ensure the right thickness and strength. For high - pressure applications, thicker steel walls may be required, while for less demanding situations, a more cost - effective thinner steel can be used.

Once the steel pipe is ready, the rubber lining process begins. The rubber is prepared in a specific formulation. It is mixed with various additives to enhance its properties. For example, fillers can be added to improve hardness or resistance to certain chemicals. The rubber is then molded or extruded to fit the inner diameter of the steel pipe precisely.

Quality control is a crucial aspect of manufacturing rubber - lined steel pipes. Before the rubber lining is applied, the steel pipe is thoroughly inspected for any surface defects such as scratches or dents. After the lining is in place, non - destructive testing methods like ultrasonic testing are often employed to check for any voids or improper bonding between the rubber and the steel. This ensures that each pipe meets the required standards for performance and durability.

2. Environmental Impact and Sustainability

In today's world, the environmental impact of industrial products is a significant consideration. Rubber - lined steel pipes can contribute to sustainable operations in several ways. The long lifespan of these pipes reduces the need for frequent replacements, which in turn decreases the amount of waste generated. Additionally, the corrosion - resistant properties of the rubber lining mean that there is less likelihood of leaks, which can prevent environmental contamination.

The rubber used in the lining can also be sourced from sustainable suppliers. Some manufacturers are increasingly using recycled rubber or rubber from sustainably managed plantations. This not only helps in conserving natural resources but also reduces the carbon footprint associated with the production of rubber - lined steel pipes.

3. Installation and Compatibility

The installation of rubber - lined steel pipes requires special attention. They need to be carefully handled to avoid any damage to the rubber lining. During installation, proper alignment is essential to ensure smooth flow of the substances being transported. Connectors and fittings used with these pipes must also be compatible. Special couplings are often designed to maintain the integrity of the rubber - lined system.

These pipes are compatible with a wide range of pumping systems. They can handle both laminar and turbulent flow conditions, depending on the nature of the fluid. For viscous fluids, the smooth rubber lining can help in reducing frictional losses, allowing for efficient transportation.

4. Cost - Effectiveness in the Long Run

Although the initial cost of rubber - lined steel pipes may be higher compared to some traditional piping options, they prove to be cost - effective in the long term. Their resistance to corrosion and abrasion means that they require less maintenance and have a longer service life. This reduces the overall cost of ownership, including the cost of downtime for repairs and replacements. In industries where continuous operation is crucial, such as in oil and gas or chemical manufacturing, the reliability of rubber - lined steel pipes can lead to significant cost savings over time.

5. Innovations and Future Developments

The field of rubber - lined steel pipes is not static. There are continuous innovations taking place. New types of rubber with enhanced properties are being developed. For example, there are efforts to create rubber linings with self - healing capabilities, which could further improve the durability of the pipes.

Research is also being done on improving the bonding technology between the rubber and the steel. This could lead to even stronger and more reliable pipes. In the future, we can expect to see rubber - lined steel pipes becoming even more efficient, sustainable, and adaptable to a wider range of industrial applications.

Key word:

Rubber lined steel pipes

Recommended